Description

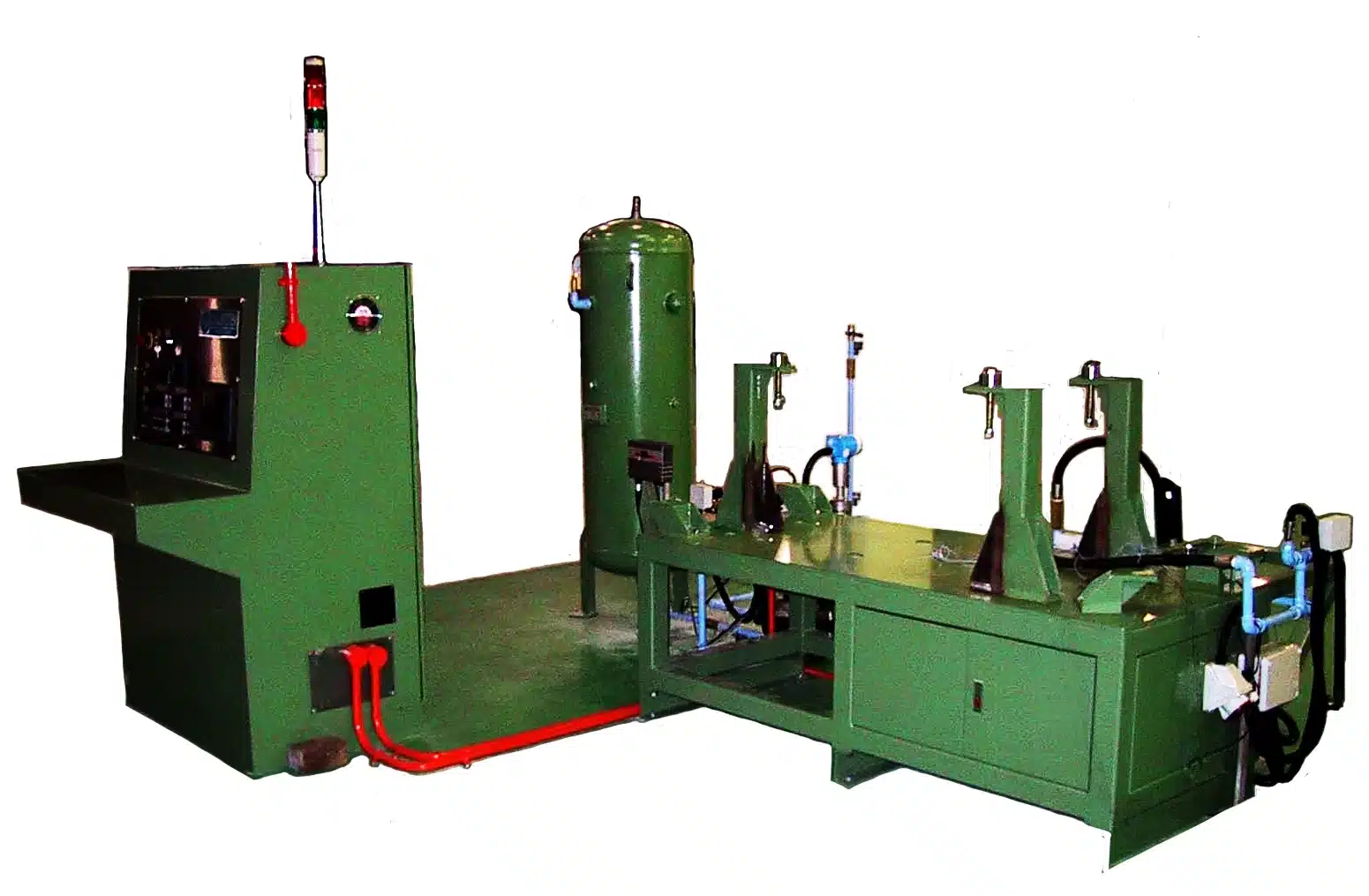

The Air Compressor Test Rig is designed for the inspection and performance testing of train carriage air compressor modules, ensuring their operational consistency and efficiency after overhaul or servicing. It evaluates the compressor’s functionality, coolant levels, and efficiency by comparing test data with factory-set parameters.

The test rig integrates various sensors to capture operational sequences and assess supporting equipment, such as Governor Pressure Switches and Dryer Units, to verify correct settings. It features PLC-controlled automation, with push-button operation for seamless testing procedures.

Key Test Parameters:

- No Load Test

- Leakage Test

- Temperature Test

- Insulation Test

- Volume Efficiency Test

The Air Compressor Test Rig operates in automatic and manual modes. In automatic mode, testing is computer-controlled, collecting data at set intervals. In manual mode, the operator controls performance parameters via an ON/OFF switch and control panel. The system also includes facilities for handling test specimens, mounting different compressor types, and integrating air reservoirs, vacuum tanks, and cooling systems. It ensures comprehensive data acquisition and report generation for reliable performance validation.