Description

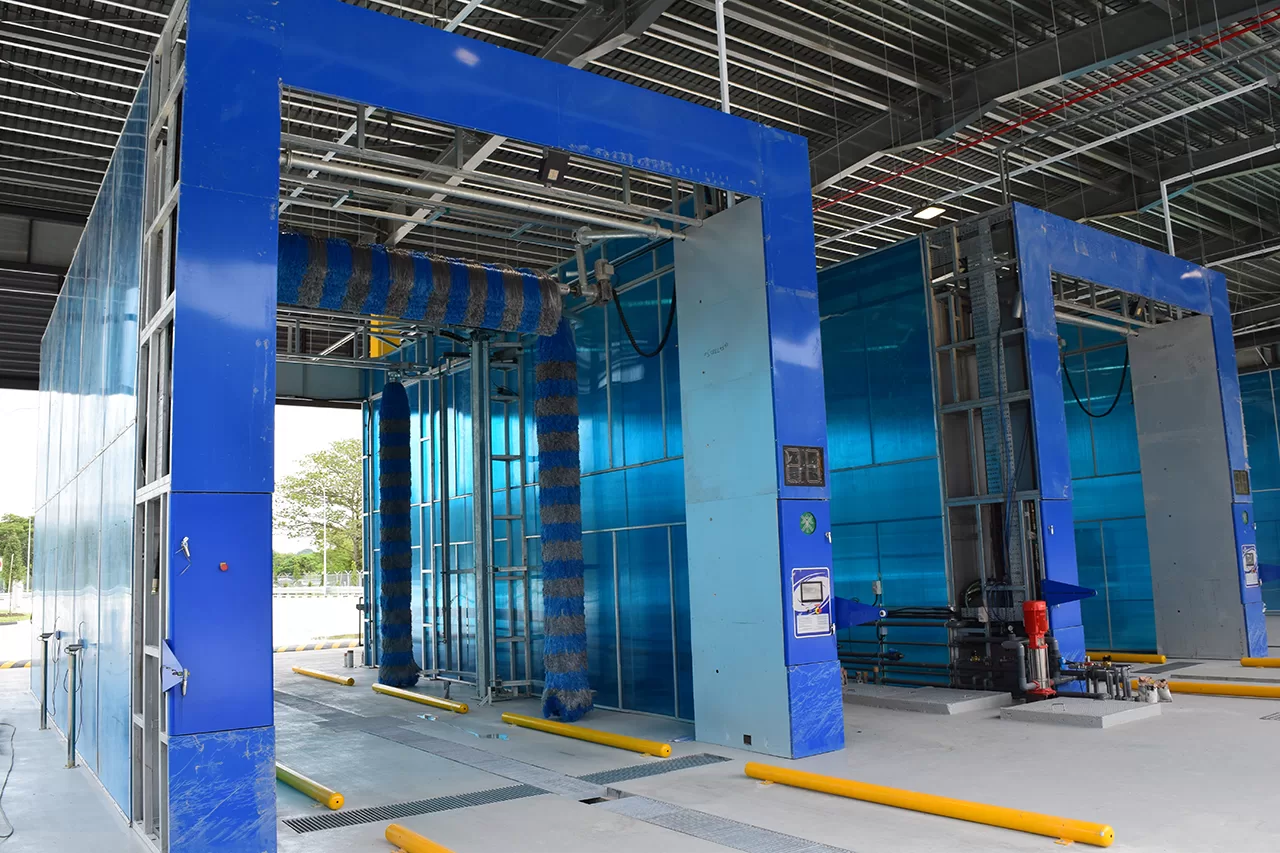

The Automatic Bus Wash System is designed for efficient and thorough cleaning of all bus types, models, and sizes. Commonly used in bus depots, it provides a fully automated cleaning process, incorporating a Side-Mirror Avoidance System, roof and double-side brush rollers, and high-pressure washing technologies. Each system is tailored to high-volume operations, offering flexible configurations to meet various operational needs and budgets.

Equipped with multiple wash methods and advanced engineering features, the system ensures optimal cleaning efficiency while minimizing maintenance downtime and spare part usage. The drive-through design allows a high throughput of up to 30 vehicles per hour, integrating brush and high-pressure spray systems for maximum cleaning performance.

The all-in-one Automatic Bus Wash System includes:

- Pre-Wetting & Detergent Spray

- Front, Rear, Roof & Side Brushing

- High-Pressure Undercarriage Washing

- Final Rinsing

The system features a self-adjusting brush mechanism, activated by a brush motor current sensor and pneumatic cylinders, ensuring optimal contact pressure for consistent and effective cleaning. Additionally, automated opening and retraction functions enhance performance and reliability.

For safety and control, a 24/7 monitoring system with sensors and a user-friendly control panel is included. The system structure is constructed from hot-dip galvanized steel, offering corrosion resistance and extended durability for long-term operation.