Description

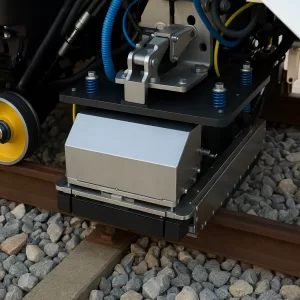

The Wheel Profile Measurement System (WPMS) is a standalone trackside measurement system, typically installed at depot entrances, designed to automatically measure wheel diameters and profiles in railway and metro systems.

The system employs high-precision line lasers and a high-speed, high-definition camera system to capture accurate measurement data. The complete WPMS setup consists of a Pick-Up Unit, Wayside Control Unit, Trackside Environmental Control Unit, Monitoring Unit, and Wayside Data Processing Unit. All collected wheel data is automatically captured, analyzed, and stored for maintenance and operational insights.